WHAT TO REMEMBER :

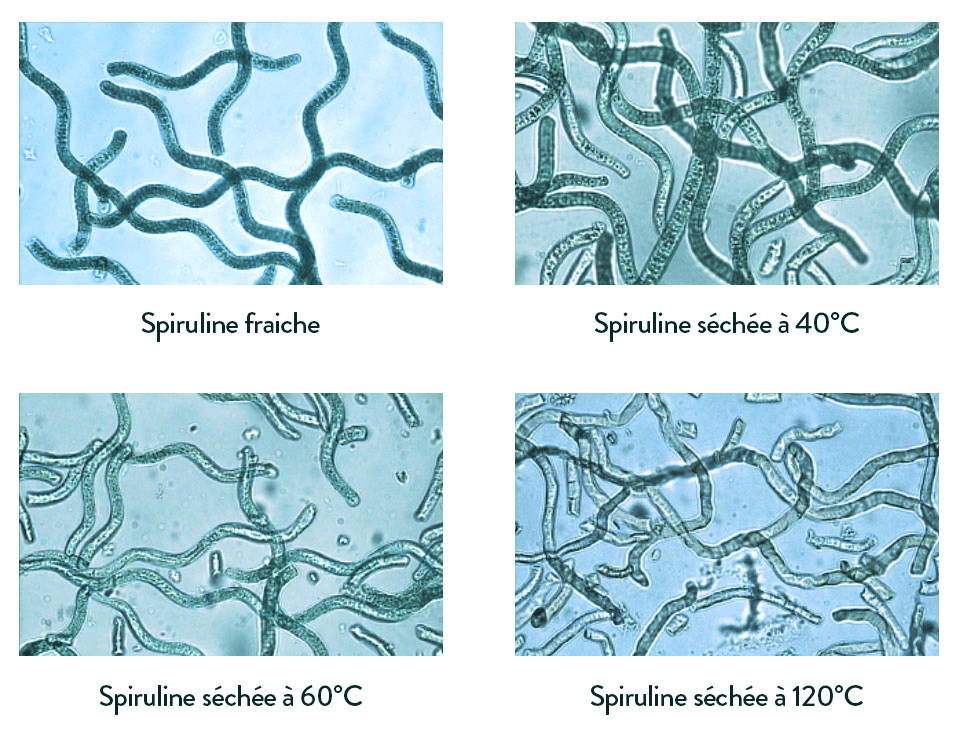

- The method of drying spirulina is debatable.

- On the Internet, we read everywhere that artisanal approaches are superior to industrial methods.

- However, science has shown the opposite: if used properly, dry spray is at least equivalent to traditional techniques.

There is no doubt that drying is a key step in the production of spirulina. Its objective is to preserve the nutritional qualities of the algae as best as possible. But the debate is about the methods used. Between marketing interests and industrial logic, it is difficult to see clearly... But we conducted the investigation and, as usual, we will deconstruct the myths !

What marketing says

In France, marketing would have us believe that there are two very different approaches to drying :

- First of all, the gas used must be neutral (without oxygen) in order to avoid oxidation during drying.

- The spirulina paste sprayed with a dry spray must be liquid enough to save the "homogenization" or grinding step. This avoids breaking the filaments of the algae, which provides better protection of nutrients.

- The tower temperature should also be set between 70° and 130° so that the air at the nozzle outlet does not exceed 50°. The integrity of proteins and vitamins is then maximum.

By following these instructions, it is possible to limit protein losses to 15%, a level equivalent to the mildest artisanal methods (<40°). Mieux encore, le temps de séchage très court (quelques secondes) évite les dégradations enzymatiques et les risques de proliférations bactériennes.

Source: H. Desmorieux et al. Biochemical and physical criteria of spirulina after different drying processes, 2005 - Claude Bernard University Lyon 1

Source: H. Desmorieux et al. Biochemical and physical criteria of spirulina after different drying processes, 2005 - Claude Bernard University Lyon 1

The image of the Spray Dry tarnished by the Chinese

But then, why does dry spray have such a bad press in France? Well because 40% of the products sold on our territory are Chinese spirulina dried via this system at very high temperature (sometimes more than 100° at the nozzle outlet). No need to detail their low nutritional profile, and let's not talk about their smell !

Why such a treatment? In fact, these farms have found a way to sell their production after extracting the phycocyanin, the famous pigment, of which the middle empire is the first consumer. The only problem is that extraction is carried out from fresh spirulina (liquid), and it is precisely when it is maintained in this form that our seaweed offers a favourable ground for bacterial proliferation. Drying at a very high temperature is the only solution to eliminate pathogens.

The team's opinion

From our point of view, the bad reputation of the dry spray is no longer justified. It is now clearly established that, if properly regulated, this process guarantees nutritional integrity at least equivalent to artisanal methods. Finally, this article would not be complete without mentioning the Refractance Window Drying® technology, considered the most gentle in the world in terms of dehydration. Already used to dry klamath (a blue-green algae very close to spirulina), it should be used on the main farms once its patent has fallen into the public domain. There is no doubt that its price will end up giving manufacturers the advantage.